| This single reinforced expansion joint is 16″ in diameter and is 15-1/8″ in length. The expansion joint is fabricated with 316L stainless steel bellows, liner, weld ends, and bellows reinforcement. This expansion joint weighs 170 lbs and is used in a feed pre-heater. It is designed and fabricated to ASME Section VIII for 581 PSIG at 842°F with a travel capacity of 0.496″ compression. 100% Dye-Penetrate testing was performed for the bellow attachment welds as well as 100% X-Ray testing on the long seam welds of the bellows and pipe ends. In addition, Hydro-testing was performed at 764 PSIG to assure quality and performance. |

Tag: Blog

188 Single Tied Expansion Joints for a Construction Company in California

These products are single tied expansion joints with 150 lb flange drilling. They were fabricated completely of 316 stainless steel. They range in size 6″ to 18″ in diameter and weigh between 40 lbs to 140 lbs each. Their travel capacity ranges from 0.88″ to 1.2″ at 25 PSIG and 180°F. The expansion joints are used in a water treatment piping system facility. The bellows longitudinal and attachment weld seams were 100% Dye-Penetrate examined. The expansion joints were pneumatically tested at 15 PSIG for performance and quality assurance.

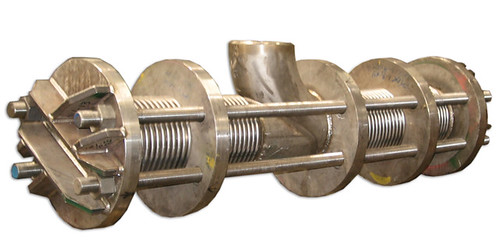

14 Single Reinforced Metal Expansion Joints for a Construction Company in Israel

These single reinforced expansion joints with equalizing rings are used in heat exchangers. The bellows are fabricated from ASTM B 443 Inconel 625 LCF. The weld ends and the reinforcing rings/root rings are carbon steel. The expansion joints are 52” and 57” diameter with an overall length of 15 ½” and 16 ½”. They are capable of moving 0.6” in extension at 158 PSIG at 300°F. The expansion joints were fabricated to ASME Section VIII. The bellows and pipe longitudinal weld seams were 100% X-Rayed. In addition, the expansion joints were 100% dye-penetrate examined and hydro tested to 205 PSIG for quality and performance assurance.

Read More3 Fabric Expansion Joints for a Power Company in Texas

These fabric expansion joints are made of stainless steel liner, flanged ends, backing bars, and PTFE impregnated fiberglass. They weigh between 370 lbs – 380 lbs and measure 81.15″ long, 18.44″ wide, and 16″ high. They are used in high temperature air ducts to allow for expansion. Its thermal growth consists of +/- 1/8 X-Y-Z directions. It is capable of withstanding 400°F at +/- 0.8 PSIG at a maximum flow of 130,650 ACFM. Standard testing was performed for quality assurance.

4 Convolution Expansion Joints for an Oil Company in India

The high-pressure expansion joint above is a single four convolution SB-443 INCO 625LCF bellow with 3 equalizing rings, 2 neck bands, 1 internal liner, and 2 weld ends all fabricated from SA-240 type 347 stainless steel. The equalizing rings enable the joint to withstand a maximum allowable pressure of 1,170 psig at 815°F. The equalizing rings allow the use of a thinner more compact and flexible bellow thereby saving space and increasing the expansion joint cycle life. This expansion joint is 14.25″ long with a calculated cycle life of 772 cycles

Read More17 Fabric Expansion Joints for a Gas Turbine Power Plant in Texas

These rectangular fabric expansion joints measure 136″ x 54″ with a weight of 135 lbs each. They were fabricated out of fiberglass fabric with stainless steel frames and are designed for ± 5 PSIG and 400°F. The expansion joints were manufactured according to specific customer specifications.

42” I.D Rubber Expansion Joints for a Power Plant in Texas

The expansion joints consist of bellows formed by 1/8” thick neoprene sheet and A36 carbon steel flanges coated with a special finish per customer’s request. These expansion joints are 42” x 7 ¾”. A dye-penetrant test was performed on the welds prior to shipping to ensure quality. The turn around for this product was four days.

Read More48 Multi-Layer High Temperature Rectangular Fabric Expansion Joints for a Gas Plant in Texas

The rectangular fabric expansion joints consisted of two carbon and stainless steel frames separated by a high-temperature Silica fabric. The frames measured 13” × 37” × 6”, 14½” × 20½” × 6” and 17¼” × 17¼” × 4” and weighed 90, 115, and 170 lb. Each expansion joint was designed for a 15” Water Column (W.C.) with a temperature of 750°F and allowed for movement ranging from ±½” to ±1” in both the axial and lateral directions.

5,165 lb. Tied Universal Expansion Joint for a Chemical Plant in Lousiana

U.S. Bellows, Inc. custom designed and manufactured a 60” diameter and 120” long universal expansion joint for a chemical plant in Louisiana.This metallic expansion joint was fabricated from 304 stainless steel bellows and carbon steel. It was designed for 10PSIG and 550°F. To ensure quality a 100% dye-penetrant, radiography, and soap leak test was performed prior to shipment.

Dual Gimbal Expansion Joints for a Regeneration Blower Outlet

This 3,400 lb. expansion joint is capable of 2.3″ lateral movement and 1.5″ axial movement and was designed for 65 PSIG and 1076ºF. It was made with SB-409 alloy 800 bellows and 316H piping and gimbal components. The dimension of this expansion joint is 24″ x 168″ x 71″. This gimbal expansion joint contains two sets of hinge pins or pivots with the axis of each set perpendicular to each other. To ensure the quality of the product, the joints were 100% X-rayed and hydro-tested at 120 PSIG prior to delivery.

3″ Diameter Universal Expansion Joints for a Power Plant Project in South Carolina

U.S. Bellows, Inc. custom designed and manufactured three 3″ diameter and 36″ long universal expansion joints for a power plant project in South Carolina. These expansion joints, fabricated from 2-ply A240-304H stainless steel bellows, are designed for 170 PSIG and 1200°F per EJMA specifications.

Read More80” Refractory Lined Tied Universal Expansion Joint

This 36’-0″ long refractory lined tied universal expansion joint weighs 54,000 lb. and has two-ply Inconel® 625 LCF bellows, tie rods, slotted hinges, insulation bags, and liner seals. It is designed to operate at 58 PSIG and temperatures up to 1,450° F. The expansion joint was preset for 6” lateral travel and is capable of lateral travel up to 13”.

Read MoreFabric Expansion Joints for Power System Company in Texas

U.S. Bellows, Inc. recently custom designed and fabricated five fabric expansion joints for a power system company in Texas. The expansion joints range in size from 30 to 62 in diameter and the rectangular expansion joints measure 81 x 18 and 136 x 54. They are designed to operate from 0.8 to 5 PSIG and in temperatures ranging from -40˚F to 400˚F. The products were fabricated using Neoprene and fiberglass fabric with carbon and stainless steel frames. A special paint system was applied per customer’s request. Additionally, the products were manufactured according to customer’s specific quality specifications.

Tied Universal Expansion Joint for Chemical Company in Texas

U.S. Bellows, Inc., recently designed and manufactured a 71″ x 84 universal expansion joint for a chemical manufacturing facility in Texas. The 3,000 lb. expansion joint was fabricated in just two weeks and replaced an existing expansion joint. This product was designed for 40 water column vacuum at 750ºF. The bellows and internal sleeves were constructed from Hastelloy C-276 and all other components were fabricated using carbon steel. The joints were 100% x-rayed and 100% dye-penetrant tested. An air test was performed at 3 PSIG for the entire expansion joint assembly prior to shipping.

Read MoreTandem Rectangular Expansion Joint for Turbine Exhaust

The expansion joint weights more than 1,700 lbs. and is capable of +/- 1/4 axial movement and +/- 1/8 lateral movement. It is designed to operate under-designed pressures ranging from full vacuum to 15 psig at 250 degrees. The bellows and liner of the expansion joint are made of 304 stainless steel with a carbon steel flange and duct. To ensure quality, the product was 100% dye-penetrant tested prior to shipping.

Read More48″ Diameter Tied Universal Expansion Joints for an Oil and Gas Company in France

U.S. Bellows, Inc. recently designed and manufactured five tied universal expansion joints ranging in size from 30 to 48 for an oil and gas company in France. These expansion joints weigh between 2400 lb. and 3200 lb. and are fabricated from 304-321 SS bellows. They are designed for pressures ranging from 55 to 650 PSIG and 148°F to 300°F operating temperatures. To ensure quality, the joints were 100% X-Rayed, 100% dye-penetrant, and hydro-tested at 83 to 975 PSIG.

Read More8″ Diameter Pressure Balanced Expansion Joints for a company in Ohio

U.S. Bellows, Inc. specially designed and fabricated two 770 lb. pressure balanced expansion joints for a company in Ohio. These expansion joints, designed for 450 PSIG and 1350 °F, will be used for wind tunnel testing of airplanes and engines. With an overall length of 70, these expansion joints consist of four 8 diameter bellows with 3 plies of Inco 625 Gr1 material, an 8 diameter Inco 800 HT elbow, four 74 A193 B8 tie rods, and four 2 thick A240 tp304H rings. To ensure quality, 100% x-ray and 100% dye-penetran tests were performed on the bellows. A pneumatic test at 550 PSIG was conducted on the entire assembly prior to shipping

Read More57″ x 96″ Rectangular Seal Expansion Joints for a Chemical Refinery in TX

U.S. Bellows, Inc. recently fabricated four rectangular primary flexible seal joints for sliding flanged connections. Designed at 2 PSIG for 1350°F, the seal joints provide for one inch of axial movement to prevent damage to flange connections. EJMA Standards and B31.3 code were used in the design and fabrication of these joints. The purpose of the rectangular seal expansion joint is to prevent leakage to the outside of the Burney Windbox. The corners are double mitered to reduce stress. Inconel® 625LCF material was used in fabricating the bellows while A240 tp 310 material was used for the frame. An air test at 5 PSIG was implemented as well as dye-penetrant test to ensure product quality.

Read More60″ Diameter Tied Refractory Lined Universal Expansion Joints for a Chemical Refinery in Texas

U.S. Bellows, Inc. recently fabricated 60 dia. refractory lined universal expansion joints for a carbon monoxide ducting system at a chemical refinery. The expansion joints are lined with a 3/4″ thick abrasion resistant refractory lining with hexagonal mesh reinforced anchor. A240 TP 304 material was used to fabricate the bellows and flanges and A240 TP 310 material was used for the spool. Designed for 2 PSIG, the joints were air tested at 5 PSIG to ensure quality performance. A dye-penetrant test was also implemented on the bellows’ long seam and attachment welds. These expansion joints were fabricated and designed per B31.3 and EJMA standards.

Read More3,212 lb. Tied Universal Joint for an Oil Piping System Application

U.S. Bellows, Inc. custom designed and manufactured a 5″ nominal diameter and 60″ long universal expansion joint for an oil piping system application in Nevada. This expansion joint consists of high strength Inconel® 625LCF bellows and A105 flanges. The expansion joint is designed for 1400 PSIG and 120°F per B 31.3 and the latest revision of EJMA standards. It is also designed to allow 4 1/2″ of lateral movement during operation. A 100% dye-penetrant and hydro-test at 2100 PSIG were preformed prior to shipment to ensure quality.

Read More