U.S. Bellows, Inc. recently refurbished a 3″ O.A.L. single bellow with flanges for a marine vessel in Texas. Within a two day span, the replacement bellow was fabricated, welded to the existing 5/8″ flanges, and shipped to the marine vessel to resume operation. The replacement bellow, fabricated from 321 stainless steel, is designed for 150 PSIG and 800° F with 0.66″ of axial movement. To ensure quality, a 100% dye-penetrant test and a soap leak test was performed prior to delivery.

Read MoreTag: Blog

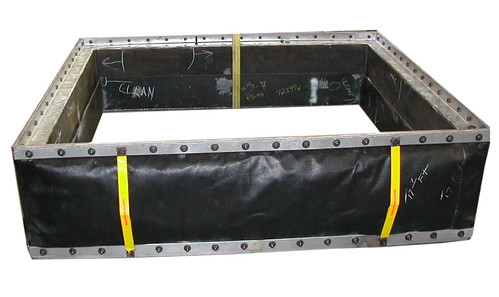

78″ x 39″ Rectangular Fabric Expansion Joint for a Power Company in Texas

U.S. Bellows, Inc. custom designed and fabricated a 315 lb. 78 x 39 multi-layer fabric expansion joint for a power company in Texas. This fabric expansion joint will be mounted inside a turbine enclosure and allows for a 15,000 cfm air flow through the enclosure. It is designed for 27 1/2 W.C. and 930°F with 0.27 axial and ± 0.12 lateral movements. The expansion joint is equipped with a stainless steel frame and a 6 thick insulated pillow which is enclosed in a stainless steel woven wire mesh.

55″ O.D. Refractory Lined Universal Gimbal Expansion Joints with Slotted Hinges for a Refinery in Joliet

U.S. Bellows, Inc. specially designed and manufactured two 55″ O.D. refractory lined universal gimbal expansion joints for a refinery in Joliet. These expansion joints are equipped with slotted hinges with an overall length of 163″ and 286″ respectively. The 163″ O.A.L. expansion joint, designed for 60 PSIG and 1020°F, will be used at the reactor standpipe of the refinery. The 286″ O.A.L. expansion joint will be used for the regenerator standpipe of the refinery and it is designed for 57 PSIG and 1300°F. Both expansion joints consist of an A516 Gr70 pipe, two SB-443 two-ply bellows, and a slotted hinge.

To ensure quality, 100% dye-penetration, 100% x-ray and pressure tests were performed on the bellows. Pneumatic and vacuum tests were also conducted on the expansion joints and between bellows dry plies prior to shipping.

Read More55″ O.D. Universal Gimbal Expansion Joints with Floating Rings for a Refinery

U.S. Bellows, Inc. custom designed and manufactured a 55 O.D. universal gimbal expansion joint with floating rings for the FCC overhead vapor line at the refinery. This expansion joint has an overall length of 310 and is fabricated from A387 Gr 11 CI2 spool and Inconel® 625 LCF bellows. It is designed for 50 PSIG and 1075°F with 13 of lateral movement.

To ensure quality, 100% dye-penetration, 100% x-ray and pressure tests were performed on the bellows. Pneumatic tests were also conducted on the expansion joint and between bellows dry plies at 55 and 15 PSIG, respectively, prior to shipping.

192″ Double Gimbal Expansion Joints for a Chemical Refinery

U.S. Bellows, Inc. designed and manufactured two 192” double gimbal Expansion joints for a chemical refinery in Channel View, Texas. These expansion joints consist of A240-321 bellows, A160 Gr. pipe, A516-70 gimbal rings, A516-70 liners and A106 Gr. B purge connection rings. The expansion joints were designed for 15 PSIG and 650 F per B 31.3 and EJMA Standards. They were also designed to allow 8 degrees of angular movement during operation. To ensure quality, the Expansion joints were air tested at 22 PSIG prior to delivery.

48” diameter Refractory Lined Expansion Joint for a Chemical Plant in Ecuador

U.S. Bellows, Inc. designed and fabricated a Refractory Lined Expansion Joint with pantographic linkages for a chemical plant in Ecuador. This expansion joint was designed for 60 PSIG and 1450 °F with a 4” thick refractory installed per UOP specifications. The bellows were constructed from SB-443 Inconel® 625, and the weld ends, hinges, pantographic linkages, and floating ring were made from A516-70.

The bellows, weld ends, and spool long seam welds were 100% X-rayed and 100% dye-penetrant tested per ASME standards. A pneumatic test was performed at 15 PSIG for the entire expansion joint assembly prior to shipping.

Read More6″ Diameter Tied Universal Expansion Joints for a Steam Reformer

U.S. Bellows, Inc. recently designed and manufactured eight 6″ diameter tied universal expansion joints with 24” F-F. These expansion joints are made from two-Ply Inconel® 625 bellows, A312 TP 304 spool, and A105 flange. They are designed for FV/50 PSIG and 300°F with axial and lateral movements of +/- 0.25″ and 0.70″, respectively. The joints were 100% X-Rayed, 100% Dye-Penetrant, and hydro-yested at 75 PSIG. Flanges, tie rod, and spherical nuts are hot dip galvanized per customer specification.

Read MoreThree 12′ x 8′ Rectangular Expansion Joints with Full Radius Corners

U.S. Bellows, Inc. recently manufactured three 12′ – 0″ x 8′ – 0″ rectangular expansion joints designed at 5 PSIG and 650 °F. The expansion joints are fabricated with full radius corners which allow for increased cycle life. The bellows are formed from Inconel® 625 SB-443 GR. 1 and the rest of the assembly is fabricated from A516-70. The long seam welds were 100% x-rayed. A 100% dye-penetrant test was performed on the attachment welds.

Read MoreThree 23″ – 1/3″ Expansion Joints for a Refinery in New Jersey

U.S. Bellows, Inc. custom designed and manufactured three 2’ – 6” OD x 23’ – 1/3” long expansion joints for a refinery in New Jersey. The bellows, pipes, and lugs were fabricated from Inco 800H high nickel alloy, A312tp 316H stainless steel, and A240tp 316H stainless steel, respectively. The expansion joints are designed for 60 PSIG, 1100°F, and 47,000 lbs. of thrust to accommodate for a high temperature application.

Read More5′ x 12′ Fabric Expansion Joint for a Power Plant in Oklahoma

U.S. Bellows, Inc. recently designed and manufactured a 5′ – 0″ x 12′ – 0″ fabric expansion joint for a hot air ducting system in a power plant in Tulsa, OK. It is designed at 15″ W.C. and 600 °F for 3/4″ axial movement and 1/2″ lateral movement. The fabric belts are composed of three layers with the outer layer serving as a waterproof barrier.

Read MoreEPDM Tied Expansion Joints for a Construction Company in Texas

U.S. Bellows, Inc. designed and fabricated 2 EPDM tied expansion joints for a construction company in Texas. These expansion joints have an inside diameter of 29”. They are composed of A516 carbon steel grade 70 with a six-rod control assembly, EPDM, and plate flange. They were hydro-tested to 217 PSI. These joints were ordered on a one-week rush basis to replace an existing joint that was leaking.

Read MoreRefractory-lined Expansion Joint for an FFC Unit in India

U.S. Bellows, Inc. designed and fabricated this refractory lined universal expansion joint for an FFC Unit in India. This is a 70″, outside diameter, tied refractory-lined universal expansion joint with two-ply Inconel® 625 LCF bellows, A516 weld ends and spool, and a 4″ thick refractory lining per UOP specifications. This joint was designed at 51 PSIG and 1400 degrees F. Bellows long seam welds were 100% x-rayed and 100% dye-penetrant before and after forming. It was also pneumatic tested at 57 PSIG the refractory lining was dried out per UOP specifications.

Read MoreExpansion Joint Exhaust Assembly for an Oil Refinery in Texas

U.S. Bellows, Inc. designed and fabricated this expansion joint exhaust assembly for an oil refinery in Texas. This expansion joint is offset for an offshore platform and weighs approximately 8,000 lbs. It has a design pressure and temperature of 1 PSIG and 1000 degrees, respectively. The air test was conducted to detect any leaks.

Read MoreRectangular Fabric Expansion Joint for Coal Fired Power Plant in Puerto Rico

U.S. Bellows, Inc. designed and manufactured a 21’ x 14′ fabric expansion joint for a power plant in Puerto Rico. This expansion joint was designed at 1 PSIG and 1200 °F for an air duct at the power plant. The frame is all A-240 and 304 stainless steel construction. This expansion joint is equipped with 6” thick insulation pillows. Telescoping liners hold the insulation pillows between the liner and the fabric belt to reduce heat transfer and prevent ash accumulation.

Tied Universal Expansion Joints for Chemical Plant in Africa

These expansion joints were designed at 170 PSIG and 450 degrees F. to absorb lateral movements and tested per B31.3. They were made with Inconel® 625LCF bellows and A105 300 lb. RFSO flanges. The entire assembly was hydro-tested at 255 PSIG and held under pressure for four hours. In order to detect any leaks, each expansion joint and its welds were subjected to the dye penetrant-test and the X-ray test, each of which were 100%, prior to and following forming.

Read More24″ In-Line Pressure Balanced Expansion Joints for a Petrochemical Plant in Venezuela

U.S. Bellows, Inc. fabricated three, 24″, inline pressure balanced expansion joints for a petrochemical plant in Venezuela. In order to absorb partial axial and lateral movements, these expansion joints were designed at 175 PSIG and 610ºF. The bellows are composed of Inconel® 625LCF material and the flanges and liners are constructed from SA516 Grade 70 material.

Read More87 Fabric Expansion Joints for a Furnace Application at a Chemical Plant in Texas

U.S. Bellows, Inc. manufactured 87, rectangular fabric expansion joints for a furnace application at a chemical plant in Texas. The joints were designed at 11″ W.C. and 750 degrees F for ½ ” axial and lateral movements. The fabric belts on these joints are composed of three layers. They were equipped with a telescoping liner and 2″ thick insulation pillows to reduce the heat transfer.

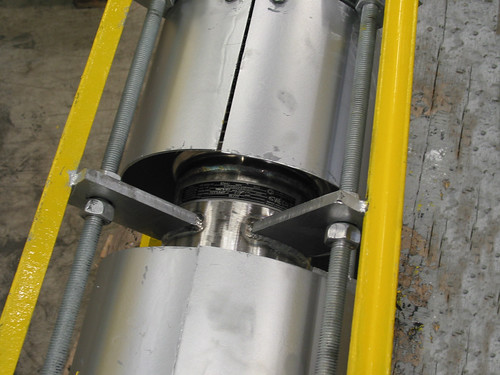

Clamshell Bellows for a Shell and Tube Heat Exchange

U.S. Bellows, Inc fabricated and installed a clamshell bellows for a shell and tube heat exchanger. The clamshell bellows are designed and fabricated per ASME VIII Div. 1 Appendix 26. It has a 14″ diameter and was designed at 150ºF and 150 psig. In order to detect any leaks, prior to and following forming, the heat exchanger and its welds were subjected to a series of tests such as the dye penetrant test (100%), X-ray test (100%) and air test

Read MoreElbow Pressure Balanced Expansion Joints for a Power Station in Canada

U.S Bellows, Inc, the expansion joint division of Piping Technology & Products, Inc., recently designed and fabricated three elbow pressure balanced expansion joints for a power station in Canada. These joints are designed at 150 PSIG and 450ºF to allow lateral and axial movements in a 42″ steam line. Expansion joints were designed and fabricated per EJMA and B31.1 code. The expansion joints were hydro-tested at 225 PSIG and 75ºF. In order to detect any leaks in the weld, prior to and following forming, bellows long seam welds and attachment welds were 100% dye-penetrant tested.

Read More14″ Diameter, Tied Universal Expansion Joints for a Power Plant in Illinois

These expansion joints were designed at 170 PSIG and 450 degrees F. to absorb lateral movements and tested per B31.3. They were made with Inconel® 625LCF bellows and A105 300 lb. RFSO flanges. The entire assembly was hydro-tested at 255 PSIG and held under pressure for four hours. In order to detect any leaks, each expansion joint and its welds were subjected to the dye penetrant-test and the X-ray test, each of which were 100%, prior to and following forming.

Read More