Expansion Joint Product Testing: Burst Testing

Objective: The objective of the burst test is to determine the ultimate pressure resistance that a bellows can absorb prior to failure. Burst tests help determine the margin of safety and safety factor to be used in a specialized bellows design.

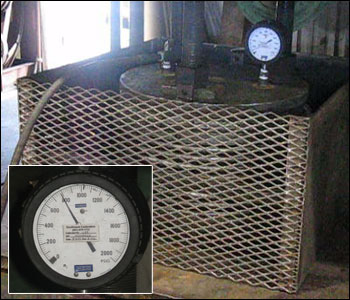

What We Do: During a burst test, hydrostatic pressure is slowly increased until failure occurs, which usually happens in one to two hours. Burst testing is conducted at ambient temperatures to determine a bellows pressure rating. We follow all the necessary safety precautions for personnel involved, such as placing the bellows in a high strength steel cage and using a safety shut-off switch.

After Completion: Based on the burst test results, a safety factor is applied, thus establishing the ultimate pressure rating.

|

|

| Burst Test to 800 psig on a 304 Stainless Steel Bellows | Q.C. Inspecting the Bellows After a Burst Test |