Metallic Expansion Joints

- Rectangular Metallic Pipe Expansion Joints

- Refractory Lined Expansion Joints

- Slip-Type Pipe Expansion Joints

- Thick Wall Pipe Expansion Joint

- Externally Pressurized (X-Flex) Pipe Expansion Joint

- Toroidal Pipe Expansion Joint

- In-line Pressure Balanced Pipe Expansion Joint

- Elbow Pressure Balanced Pipe Expansion Joint

- Gimbal Pipe Expansion Joint

- Hinged Pipe Expansion Joint

- Universal Pipe Expansion Joint

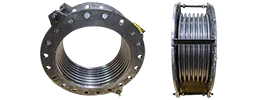

- Single Pipe Expansion Joint

Refractory Lined Expansion Joints

Slip-Type Pipe Expansion Joints

Thick Wall Pipe Expansion Joint

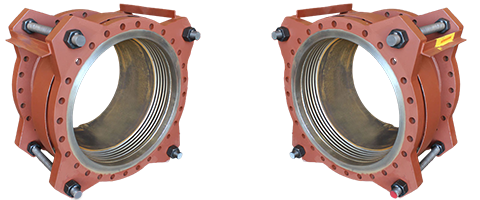

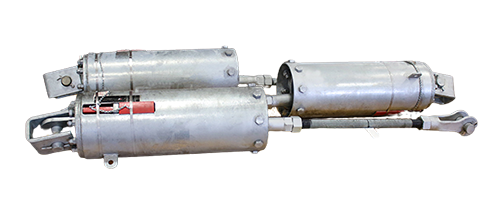

Externally Pressurized (X-Flex) Pipe Expansion Joint

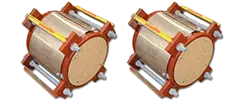

Toroidal Pipe Expansion Joint

In-line Pressure Balanced Pipe Expansion Joint

Elbow Pressure Balanced Pipe Expansion Joint

Gimbal Pipe Expansion Joint

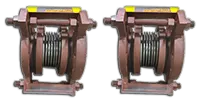

Hinged Pipe Expansion Joint

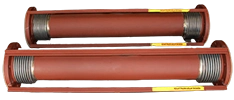

Universal Pipe Expansion Joint

Single Pipe Expansion Joint

"US Bellows engineer has been really helpful in ensuring that we get this order expedited and that we make sure to iron out all the details to ensure we get the best product."

Expansion Joints Metal Bellows - March 2023

"I sincerely thank all of you for your efforts to date and encourage all of you to continue the excellent performance and commitment to the projects."

Single Expansion Joint - 2020

"Work is always completed when they say that it will be completed."

Expansion Joints Metal Bellows - November 2022

"I cannot be happier to deal with the engineers at PTP. The quote process has been extremely easy...

Read More

Expansion Joints - April 2023

"Your engineers were a tremendous help in getting this order pushed thru for a quick turnaround to support our field needs."

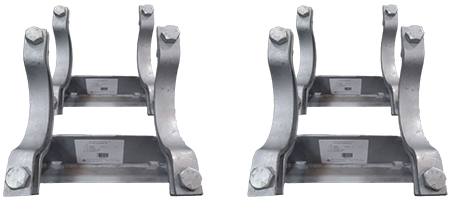

Fabricated pipe shoes, guides, anchors - November 2021

"My impression of your technical and production engagement is very positive."

Expansion Joints Metal Bellows - January 2021

"As always, I appreciate the prompt support provided by PT&P team and I know, I can count on it every time."

Expansion Joints Metal Bellows - December 2022

"The US Bellows team was very professional and help guide me through the process."

Expansion Joints Metal Bellows - April 2024

"Responsive team!"

Expansion Joints Metal Bellows - March 2023

"Good experiences with you all on Expansion Joints in the past."

Expansion Joints Metal Bellows - October 2021

"PT&P continues to provide excellent products and a world-class customer service experience..."

Read More

Misc. Steel fabrication - February 2022

"PT&P provides excellent sales and product support. The company clearly makes an effort to be clear about design selection, order support and product delivery. Keep up the good work."

Pipe Hanger Hardware - December 2021

"As a Mechanical Engineer, I like the products & complimentary webinars Piping Technology & Products offers."

Expansion Joints Metal Bellows - September 2022

"Thank you very much for the excellent work you and your associates at PTP/USB provided on my order..."

Read More

High Temperature Insulated Supports - December 2021

"Thank you for getting the Spring Cans to us quickly. They were actually made a couple of days ahead of projection..."

Read More

Variable Assemblies - August 2022

"We are pleased with the Customer Service and care we have received from our project."

Fabric Expansion Joint - November 2021