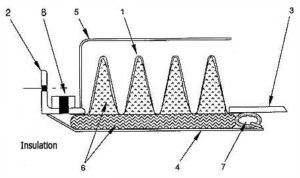

1. Bellows

2. Angle Flange

3. Weld End

4. Liner (Baffle)

5. Cover

6. Particulate Barrier/Insulation

7. Liner Seal

8. Purge

The bellows is the flexible element of the expansion joint. It must be strong enough circumferentially to withstand the pressure and flexible enough longitudinally to accept the deflections for which it was designed, and as repetitively as necessary with a minimum resistance. This strength with flexibility is a unique design problem that is not often found in other components in industrial equipment.

Internal liners are used to reduce turbulence across the bellows, and to protect the bellows from erosion. They are necessary when particulate barriers and purges are specified. Liners are normally required when ducts are refractorily lined, as they become refractory lined as well. Applicable lateral and angular movements should be specified, in order that adequate clearance is provided in the liner design. Flow direction should be specified on expansion joints with combination ends.

External covers are recommended to protect the bellows from mechanical damage. They may also be utilized for the application of insulation when the ductwork is insulated as well. Covers may be provided in removable and non-removable configurations.

Particulate Barrier/Purge Connections

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purging systems may also be used to perform this function. Liners will necessarily have to be installed when a particulate barrier or purge connection is specified.

Rectangular expansion joints may come equipped with hinges, tie rods, etc., that can be used to control movements, restrain pressure thrust, or support external loads. This hardware may be installed internally or externally.

| ACCESSORIES | |

| TYPE | USES AND ADVANTAGES |

| INTERNAL SLEEVES |

1. Minimize the pressure drop through the expansion joint. 2. Prevent vibration of bellows induced by high velocity, turbulent flow. 3. Prevent erosion of bellows in abrasive services. 4. Internally insulate bellows in high-temperature services. |

| ANCHOR BASE |

1. Divide piping into two separate segments ensuring proper movement of each bellows in double type expansion joint. |

| EXTERNAL COVER |

1. Protect bellows against mechanical damage during installation and in-service. 2. Protect personnel in hazardous services. 3. Serve as support for external insulation. |

| PURGE AERATION CONNECTIONS |

Used in conjunction with an internal sleeve too: 1. Prevent packing, “coking”, of flue-solids between internal sleeve and bellows. 2. Introduce coolant between bellows and internal sleeve in very high-temperature service. |

| TIE RODS |

1. Prevent application of pressure thrust to piping, or equipment when expansion joint is used for lateral deflection and/or angular rotation only. 2. Used as limit rods on expansion joints for axial movement. Limit over-extension of joint and damage to piping or equipment if anchor fails. 3. Used as control rods to limit and control the movement of universal type expansion joints. |

| OVERSIZED BELLOWS |

1. Permit use of internal sleeve for joint moving laterally or angularly without reducing inside diameter. 2. Used in conjunction with an internal sleeve to reduce bellows temperature in very high-temperature service. |