|

|

|

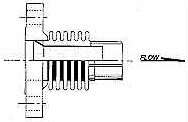

Internal liners or baffles are a recommended accessory to extend the life of many metallic pipe expansion joints because of their ability to protect the convolutions from direct flow impingement, which can cause erosion and flow-induced vibration. Internal liners should be used when internal flow conditions exceed the following criteria:

|

|

|

Air, Steam and other Gases 1) up to 6-inch dia. – 4 ft/sec per inch of dia. 2) over 6-inch dia. – 25 ft/sec. Water and other Liquids 1) up to 6-inch dia. – 1-2/3 ft/sec per inch of dia. 2) over 6-inch dia. – 10 ft/sec. When turbulent flow is generated within ten pipe diameters of the pipe expansion joint by changes in flow direction, valves, tee or elbow sections, cyclic devices, etc., the actual flow velocity should be multiplied by four prior to utilizing the criteria of the Standards of the Expansion JointManufacturers Association Sections C-3.1.2 and C-3.1.4.

|

|

|

The standard PT&P internal liner is made of 300 Series stainless steel. If corrosion or temperature considerations dictate, the liner can be made of the same material specified for the bellows. The liner is a longitudinally welded tube attached at one end to the upstream end connection. The diameter of the liner is small enough that the free, downstream end will not interfere or contact the downstream end connection during lateral or angular deflections. When a standard pipe expansion joint is selected from this catalog with the internal liner accessory, the expected lateral deflection should be stated so that the liner diameter can be properly sized. If expected flow rates will be very high, such as at steam safety relief valves or in turbine exhaust and extraction steam applications, the internal liner should be of heavier construction. Usually, the liner material can be the same as the system pipe material, such as carbon steel, with liner thickness’ of 1/8-inch and greater depending upon flow rate and diameter. Internal liners are almost always welded into the pipe expansion joint. However, if the Van-Stone flange end connection is specified, the PT&P liner will have its own flange and will be captured between the flanges at the upstream connection into the piping. |

|

Request A Quote