By John Demusz

June 24, 2010

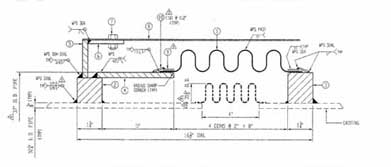

Most fixed tube heat exchangers have an expansion joint on the shell side of the exchanger. The shell side expansion joint compensates for the differential thermal growth between the tube and the shell under operating conditions. If the expansion joint would start to leak, it can cause serious operational and safety issues. Replacing a bellows in a heat exchanger is viewed as an extremely expensive process since the tubes must be removed from the tube sheet to replace the bellows.

|

|

US Bellows can retrofit your heat exchanger bellows without removing the tubes from the tube sheet. Our “clam shell technology” enables US bellows to remove the existing leaking bellows and replace it by installing a clam shell bellows. The clam shell bellows is fabricated by removing the existing bellows and obtaining precise dimensions to correctly fabricate a new bellows. The new bellows will be formed to the exact dimensions of the heat exchanger then cut into two pieces. Both halves of the bellow will be installed on the exchanger by welding the two halves together. The longitudinal bellows welds will be dye-penetrant examined for quality assurance. The new bellows replacement can also be hydro-tested in our facility.

US Bellows/Sweco Fab. Maintain ASME code U Stamp and R stamp which are renewed every three years. Materials or construction meet our customer’s specific requirements for all types of media, pressure, and temperature conditions. Clam shell bellows can save thousands of dollars.