U.S. Bellows designed a universal expansion joint and duct work assembly for a 3rd pass outlet converter to economizer duct work application at a chemical plant in 8 weeks. Expansion joints are used in many economizer ductwork applications near boilers. Plant turnarounds are a vital part of a plant’s maintenance program. They involve a scheduled stoppage of part or all of a plant’s operations. During this time, existing equipment such as expansion joints are removed and replaced with new or upgraded expansion joints. On-time delivery is critical to the plant turnaround schedule in order to limit the amount of time the plant is in shutdown. The total assembly included a universal expansion joint, over 125 feet of custom-built 60” diameter duct work, including elbows, tees, saddles, nozzles, and spring supports. The expansion joints were designed for 0.3 degrees angular movement, 2.875″ lateral, and 3.25″ axial extension. The design conditions were 5 psig at 890 degrees F. The liner, cover, and ducting are fabricated from 304 stainless steel and the bellows are 321 SS. A dye penetrant exam, soap & air test, and spot x-ray on all duct seam welds were performed before shipping. U.S. Bellows has worked extensively on boiler units within the chemical industry and has provided products and designed supports for the unique requirements of economizers including the use of stainless steel and super alloys to support applications such as this involving highly corrosive media.

Read MoreTag: duct work

90″ Dia. Duct Work Designed for an Ammonia Plant in Louisiana

U.S. Bellows custom designed and fabricated this 90″ diameter radius long elbow duct assembly for an ammonia plant in Louisiana. The duct assembly shown here is being sent for painting before it is shipped. The assembly was fabricated from A-516 Gr. 70 carbon steel material and designed for 16 psig and full vacuum at 302°F. A 100% dye penetrant test, and spot x-ray test of all pipe circumferential and long seam welds was performed prior to shipment.

Read MoreDuct Work Custom Designed with Turning Vanes

U.S. Bellows custom designed duct work with turning vanes in the elbows for a dry tower leading to a main gas blower inlet. The duct work assemblies are fabricated from 316L stainless steel and designed for temperatures up to 150°F. The total assembly is 66″ diameter and 749-5/8″ long. The units were x-rayed, dye penetrant tested and hydro-tested prior to shipment.

Read MoreDuct Work and Expansion Joint Assembly Custom Designed by U.S. Bellows for an Oil Refinery in California

This duct work and expansion joint assembly was custom designed by U.S. Bellows for an oil refinery in California. The project consists of 36″ x 48″ 304 stainless steel oval shaped duct work with a thick wall expansion joint and 30″ x 16″ carbon steel round shaped duct work. It is designed for 900°F at 13.2 psig, and the entire assembly was dye penetrant examined and 100% x-rayed prior to shipment.

What type of media can pass through a transition piece?

Media that can pass through a transition piece include air, liquid, gasses, dust,dirt, and chemicals.

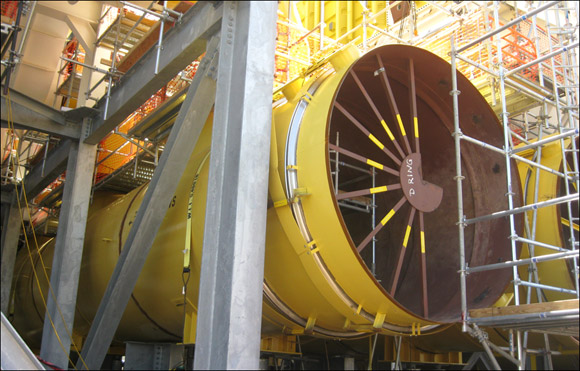

Read More102″ Dia. Single Hinged Expansion Joint and Duct Work Assembly and Two 92″ Single Expansion Joints

U.S. Bellows designed a 102″ dia. single hinged expansion joint and duct work assembly, along with two 92″ single expansion joints for a coal gasification facility in Mississippi. Both the assembly and expansion joints were fabricated from carbon steel with 304 stainless steel bellows, and designed for 3.6° angular movement at 825°F and 3 psig. The expansion joints were dye penetrant examined, 100% x-rayed and soap and air tested prior to shipment.

Read MoreEngineering, Design and Fabrication of 119″ Expansion Joints, Duct Work and Supports

U.S. Bellows provided the total engineering, design, and fabrication package for this project including expansion joints, elbows, duct work, saddle supports, F-type variable spring supports, slide plates, and pipe anchors.

A total of twelve, 119″ dia. double-slotted hinged expansion joints, thirty-six, 72″ dia. elbows, and twelve, 119″ dia., 55″ long header ducts were fabricated for a power plant in Mississippi. The expansion joint assemblies were designed for .5° angular movement, 3/8″ lateral, 1-1/2″ axial compression. The design conditions were 5 psig at 300°F. The duct work was fabricated from A-36 carbon steel material and the bellows were fabricated from 304 stainless steel. A dye penetrant exam, soap and air test, and spot x-ray on all duct seam welds were performed prior to shipping.

Read More84″ Diameter Duct Work and Fabric Expansion Joint Assemblies

The two assemblies shown, a mitered elbow duct work and fabric expansion joint and duct work assembly, are designed for a sulfuric acid plant. Both assemblies are fabricated from 1/4″ thick 304L stainless steel. They are designed for a 15″ water column with a temperature of 180°F, axial compression of 3/4″, and lateral movement of 3/4″. A dye penetrant examination is performed on all welds prior to shipment.

90″ Universal Flanged and Flued Head Expansion Joint and Duct Work Assembly

This universal flanged and flued head expansion joint and duct work assembly is designed for a 90″ diameter line. It includes slotted hinge plates installed across the bellows to carry the weight of the duct between the bellows and equalize the axial compression between the two bellows. The flanged and flued heads, duct and weld ends are fabricated from 304 H stainless steel. The expansion joint is designed for 2″ axial compression, 2-1/2″ lateral deflection, and 1150°F at 5 PSIG. A spot x-ray test, soap and air test, and 100% dye penetrant exam were performed prior to shipment

Duct Work for Absorbing Tower Piping in an Acid Plant

This duct work was fabricated with mitered elbows from SA-516 grade 70 carbon steel, and was designed for absorbing tower piping in an acid plant. It has a 72″ outside diameter and measures 23″-2/4″ from the centerline, elbow to elbow. This assembly was only a single portion of a duct work system that included 36″, 48″ and 60″ diameter sections of fabricated duct work. The duct work was fabricated with roundness tolerance of +/- 1/8″. A 100% dye penetrant test, soap and air test, and spot x-ray testing of all pipe circumferential and long seam welds was performed prior to shipment.

78″ Fabric Expansion Joint and Duct Work Assembly with a 90° Elbow for a Sulphuric Acid Plant

U.S. Bellows designed and fabricated a 78″ fabric expansion joint and duct work assembly with a 90° elbow for a sulphuric acid plant in Louisiana. A stress analysis was performed to determine thermal movements and spring supports, loads and travel.

The ducts are fabricated from carbon steel and are 30″ long. The expansion joint is designed for 750°F at 5 PSIG with 2.5″ lateral deflection (cold preset) and 2″ axial compression. Cradle supports and a “big ton” spring support were also fabricated for this project.

Read MoreHow do you analyze duct work?

We use CAESAR II software to conduct pipe stress analysis on duct systems.

60″ Ductwork with Spring Supports, Snubbers, a Support Cradle and a Fabric Expansion Joint

U.S. Bellows, Inc. and PT&P combined to furnish a fabric expansion joint, duct work, a spring support cradle and snubbers. US Bellows furnished a fabric expansion joint with acid resisting fabric and also a duct work measuring 34″ long and 60″ in diameter which was fabricated from ASTM A 516GR 70 carbon steel. PT&P furnished spring supports, carbon steel cradle supports, and snubbers. The expansion joint was completed within 6 weeks in time for a plant shutdown. A computerized pipe stress analysis, utilizing the Caesar II stress program, was performed to obtain the forces and moments imposed on the equipment nozzles and weights to be carried by the spring supports.

Read More