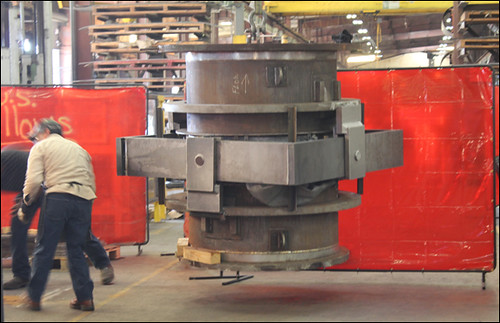

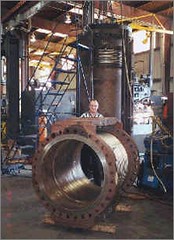

U.S. Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 psig up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied Material Test Reports per the client requirements.

Read More