Tag: rectangular expansion joint

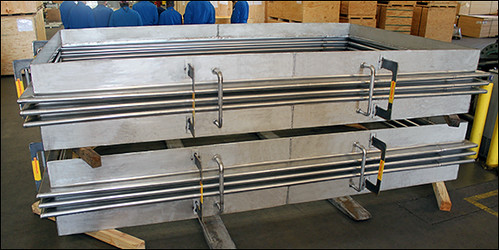

24 Foot Long Universal Expansion Joint Custom Designed for a Steam Turbine

| Type: | Rectangular metallic Universal Expansion Joint |

| Size: | 291.75″ long x 62″ wide x 76″ high |

| Design: | Operating Temperature Range: 850°F Pressure: 1.5 PSIG Movement: 1.5″ Axial Compression |

| Material: | A36 Carbon Steel and 304 Stainless Steel |

| Testing: | 100% Dye Penetrant Test and Pneumatic Test |

U.S. Bellows custom designed this universal rectangular expansion joint for a steam turbine facility in Alaska. The bellows and liner were fabricated from 304 stainless steel and the weld ends from A36 carbon steel. The unit is 62″ wide, 291.75″ in length, and 76″ in height. It is designed for an operating temperature up to 850°F at 1.5 psig and 1.5″ of axial compression. The expansion joint was 100% dye-penetrant tested and pneumatic tested prior to shipment.

Read MoreCustom Designed Rectangular Expansion Joints for a Chemical Plant in Texas

| Type: | Rectangular Expansion Joint |

| Size: | 91″ x 130″ x 24″ |

| Design: | 304 Stainless Steel |

| Material: | 482°F at 14.2 psig & 1″ Axial Compression |

| Testing: | Soap & Air and 100% Dye-Penetrant |

These rectangular expansion joints was custom designed by U.S. Bellows for a chemical plant in Texas. It has dimensions of 91″ x 130″ x 24″. It was completely fabricated from 304 stainless steel. The units are designed for an operating temperature of 482°F with an operating pressure of 14.2 psig and 1″ of axial compression. The expansion joints were soap & air tested and 100% dye penetrant tested prior to shipment.

Read MoreRectangular Metallic Expansion Joint for an Oil Refinery in Texas

| Type: | Rectangular Expansion Joint |

| Size: | 148″ x 148″ and 17″ FTF |

| Design: | 316 Stainless Steel |

| Material: | 350°F at +50″ water column and 1.5″ Axial |

| Testing: | 100% Dye-Penetrant and Air & Soap |

This rectangular metallic expansion joint was custom engineered for an oil refinery in Texas. The unit’s dimensions are 148″ x 148″ and 17″ face-to-face length. The bellows, flanges, and hardware were completely fabricated from 316 stainless steel. It is designed for an operating temperature of 350°F at +50″ water column and 1.5″ of axial compression. The unit was 100% dye-penetrant and air & soap tested prior to shipment.

Read More107″ Custom Rectangular Expansion Joint for a Refinery in Texas

| Type: | Rectangular Expansion Joint |

| Size: | 107″ x 71″ x 64″ |

| Design: | 304 Stainless Steel and Carbon Steel |

| Material: | 250°F at 15 psig and 0.125″ of lateral deflection |

| Testing: | Soap & Air, 100% Dye-Penetant, and Pneumatic |

This rectangular expansion joint was custom fabricated by U.S. Bellows for a refinery in Texas. The expansion joint is 107″ in height, 71″ in width, and 64″ in length. The bellows and cover were fabricated from 304 stainless steel and the rest of the components from carbon steel. It is designed for 250°F at 15 psig and 0.125″ of lateral deflection. The expansion joint was soap & air, 100% dye-penetant, and pneumatic tested prior to shipment.

Read More9′ Rectangular Metallic Expansion Joint Designed for a Gas Turbine Facility

| Type: | Rectangular Expansion Joint |

| Size: | 106″ x 72″ x 15″ |

| Design: | 310 Stainless Steel Bellows / Carbon Steel |

| Material: | -20 – 1000°F / +/- 5″ water column |

| Testing: | 100% dye-penetrant tested |

U.S. Bellows designed this rectangular expansion joint for a gas turbine facility in California. It was custom designed with one 6″ x 6″ square convolution. The dimensions for unit are 106″ x 72″ x 15″. The bellows was fabricated from 310 stainless steels and the frame from carbon steel. It is designed for an operating temperature from -20°F to +1,000°F at +/- 5″ water column. The unit was 100% dye-penetrant tested prior to shipment.

Read More75″ Long Rectangular Expansion Joint Designed for a Boiler Exhaust Application

U.S. Bellows designed and fabricated this rectangular metallic expansion joint for a boiler exhaust application. The expansion joint is 45½” x 75½”. The unit’s bellows, liner, and angle flanges are 304 stainless steel and the cover is carbon steel. The expansion joint is designed for an operating temperature of 500°F at 15 psig. A 100% dye penetrant examination and air and soap leak test was performed prior to shipment.

Read MoreRectangular Metallic Expansion Joint with Cor-ten Flanges and Refractory Lining for a FCC Duct

|

This rectangular metallic expansion joint is fabricated with 321 stainless steel bellows and Cor-ten flanges. The inside of this unit is lined with both vibra cast and abrasion resistance refractory. The dimensions are 65″ x 81″ x 41-1/2″ overall length and the assembly weighs 3,900 lb. All welds are 100% dye penetrant examined and the design conditions are 1400°F with 5 PSIG.

Read MoreU.S. Bellows, Inc. Designed and Fabricated a 55′ Long by 14’6″ Rectangular Metal Expansion Joint for a Power Plant

U.S. Bellows, Inc. fabricated two metallic expansion joints on an expedited schedule. The expansion joints were fabricated from COR-TEN ASTM 588 carbon steel and are designed for 1.2 PSI at temperatures up to 748°F. The expansion joints were designed for an axial compression of 1.5″ and a lateral resultant movement of 1.84″. The entire expansion joint was shipped to the job site in one piece. This avoided having to splice weld the expansion joint into one piece, which saved the customer countless assembly man hours in the field.

Read MoreRectangular Metal Bellows with Round Corners

These rectangular metal bellows are fabricated entirely from ASTM A-240 type 304 stainless steel. The larger bellows measures 240″ x 80″. The smaller bellows measures 157″ x 65″. The design conditions were 1 PSIG at 1,000°F. Both metal bellows are designed with three convolutions with round corners. The metal bellows welds were 100% dye-penetrant examined and soap and air tested prior to shipment. These bellows are designed to be installed at the ductwork connection to a large steam boiler.

Read MoreU.S. Bellows, Inc. Designed and Fabricated an 84″ Long Rectangular Metallic Expansion Joint

|

This rectangular metallic expansion joint measures 22″ x 84″ x 11″ face-to-face and is fabricated from 316 stainless steel bellows and carbon steel flanges. This expansion joint is designed to absorb axial compression in a hot air duct system to a fan inlet. The bellows have three convolutions with mitered corners. The expansion joint was 100% dye-penetrant examined and soap and air tested prior to being shipped to a power plant.

Read MoreResponded to Local Emergency by Refurbishing 36″ Rectangular Metal Expansion Joint

|

U.S. Bellows, Inc. refurbished a rectangular metal expansion joint on an emergency basis for a local chemical plant. Upon arrival, the expansion joint was acid washed and dye-penetrant examined for any cracks in the metal. The expansion joint bellows were then repaired, retested and sent back to the customer in a matter of two days. The expansion joint measures 21″ x 26″ x 36-3/8″. The bellows are fabricated from Inconel® 625 LCF material. The rest of the assembly is fabricated from Inconel® 600 material. The design temperature is 660°F and the design pressure is 20 PSIG. The expansion joint was soap-air bubble tested and dye-penetrant examined before being returned.

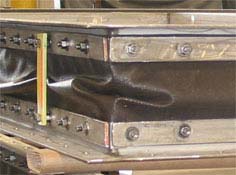

Read MoreU.S. Bellows, Inc. Designed and Fabricated Fabric Expansion Joints for a Power System Company in Texas

|

|

Expansion Joint Ready for Inspection |

Read More

U.S. Bellows, Inc. recently custom designed and fabricated 17 rectangular fabric expansion joints for a power system company in Texas. The expansion joints measure 54″ x 136″ and weigh 135 lb. each. They are designed for operation up to 5 PSIG and temperatures up to 400°F. The expansion joints are made of fiberglass fabric and have stainless steel frames

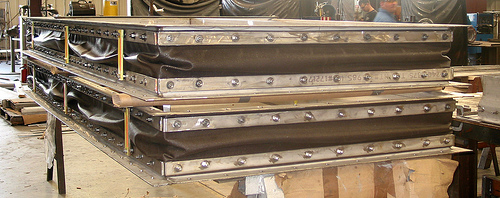

Tandem Rectangular Expansion Joint for Turbine Exhaust

The expansion joint weights more than 1,700 lbs. and is capable of +/- 1/4 axial movement and +/- 1/8 lateral movement. It is designed to operate under-designed pressures ranging from full vacuum to 15 psig at 250 degrees. The bellows and liner of the expansion joint are made of 304 stainless steel with a carbon steel flange and duct. To ensure quality, the product was 100% dye-penetrant tested prior to shipping.

Read More57″ x 96″ Rectangular Seal Expansion Joints for a Chemical Refinery in TX

U.S. Bellows, Inc. recently fabricated four rectangular primary flexible seal joints for sliding flanged connections. Designed at 2 PSIG for 1350°F, the seal joints provide for one inch of axial movement to prevent damage to flange connections. EJMA Standards and B31.3 code were used in the design and fabrication of these joints. The purpose of the rectangular seal expansion joint is to prevent leakage to the outside of the Burney Windbox. The corners are double mitered to reduce stress. Inconel® 625LCF material was used in fabricating the bellows while A240 tp 310 material was used for the frame. An air test at 5 PSIG was implemented as well as dye-penetrant test to ensure product quality.

Read MoreThree 12′ x 8′ Rectangular Expansion Joints with Full Radius Corners

U.S. Bellows, Inc. recently manufactured three 12′ – 0″ x 8′ – 0″ rectangular expansion joints designed at 5 PSIG and 650 °F. The expansion joints are fabricated with full radius corners which allow for increased cycle life. The bellows are formed from Inconel® 625 SB-443 GR. 1 and the rest of the assembly is fabricated from A516-70. The long seam welds were 100% x-rayed. A 100% dye-penetrant test was performed on the attachment welds.

Read More71″x143″ Rectangular Expansion Joint for an Oil Refinery in India

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and fabricated a 71 x 143 rectangular expansion joint for an oil refinery in India. The expansion joint was fabricated from SS 316 L, designed at 18 psig at 417°F. It is equipped with a liner and rounded corner bellows design. EJMA Standards and B31.3 code were used in the design and fabrication of this joint.

Read More28″x 66″ Rectangular Expansion Joint For Chemical Plant In South Carolina

U.S. Bellows, Inc. manufactures a stainless steel rectangular expansion joint, 28” x 66”, for an exhaust system at a chemical plant in South Carolina. This joint is equipped with a liner, tie rods system and mitered corner bellows design. The expansion joint was designed for 15 psig at 600°F and leak tested. A 100% dye-penetrant test was also performed on all the welds.

Read More