U.S. Bellows designed this universal gimbal hinged expansion joint for a methanol and ammonia plant in Texas. This expansion joint is 48″ in diameter and 145″ OAL. The bellows were fabricated from Inconel 625 and the assembly is carbon steel. The unit is designed for an operating temperature of 752°F at 50 psig, the angular spring rate is 4,374 lb/in., with 3/4″ of axial movement within the gimbal bars. The unit was 100% x-ray, dye-penetrant, and hydro-tested prior to shipment.

Read MoreTag: Universal Expansion Joint

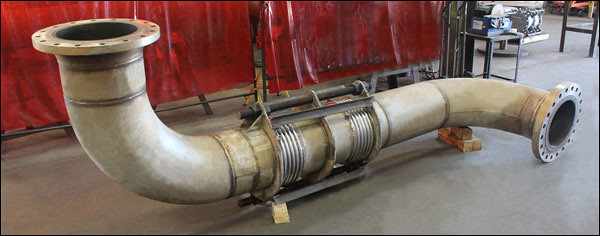

134″ Tied Universal Elbow Pressure Balanced Expansion Joint designed for a Chemical Plant in Arkansas

U.S. Bellows designed this tied universal elbow expansion joint for a chemical plant in Arkansas. The bellows, pipe, and liner were made from 304 stainless steel and the tie rods and cover from carbon steel. The expansion joint is 30″ in diameter and 134″ center line to center line of the elbow. It is designed for an operating temperature of 450°F at 200 psig and 2″ of axial lateral. All butt welds were 100% x-rayed and the remaining welds were dye penetrant examined. The complete unit was hydrotested prior to shipment.

10″ Dia. Universal Expansion Joints for HVAC Service in California

U.S. Bellows designed these universal expansion joints with flanges for HVAC services in California. The bellows are fabricated from 304 stainless steel, the flanges from A105 carbon steel, and pipe from 106 Gr. B carbon steel. The expansion joints in this project ranged from 3″ to 10″ in diameter, and are designed for an operating temperature of 160°F to 353°F at 120-125 psig, with an axial compression of 1.5″ and a lateral deflection of 1.3″. All expansion joints were 100% dye-penetrant tested and hydro-tested prior to shipment.

136″ Dia. Universal Expansion Joint for a Thermal Power Plant

U.S. Bellows designed this universal expansion joint for a thermal power plant in Oregon. The expansion joint is 136″ in diameter and 36″ in OAL. The bellows are fabricated from stainless steel and the flanges and pipe are carbon steel. It is designed for a lateral movement of 1/2″ at 250°F and 15 psig. The expansion joint was 100% dye-penetrant tested prior to shipment.

Stainless Steel Universal Expansion Joints for a Pipeline in Taiwan

U.S. Bellows designed these universal expansion joints with limit rods for a pipeline in Taiwan. The expansion joints are 4″ diameter by 18″ length. The bellows are fabricated from 304 stainless steel and the flanges are 316 stainless steel. They are designed for an operating temperature of 150°F at 150 psig, with a compression of 1.5″ and a lateral deflection of 0.5″. All expansion joints were 100% dye-penetrant tested and hydro-tested prior to shipment.

8″ Dia. Tied Universal Expansion Joint Designed for a Pipeline in Colorado

U.S. Bellows designed 8″ diameter tied universal expansion joints for a pipeline in Colorado. The bellows are fabricated from 321 stainless steel and the flanges, pipe, and tie rods are carbon steel. They are designed for a lateral movement of 5″ at 400°F and 200 psig. The lateral force to deflect the units 5″ is 116 lb. The expansion joints are rated for a 7,000 cycle life and were 100% dye-penetrant tested and hydro-tested prior to shipment.

12″ Dia. Tied Universal Expansion Joint Designed for a Power Plant

U.S. Bellows custom designed this tied universal expansion joint for a power plant. The expansion joint is 12″ Dia. x 34 1/2″ OAL. The bellows are fabricated from Inconel 625 LCF and the tie rod ring attachments, pipe and tie rods are 316 stainless steel. It is designed for an axial movement of 1/2″, a lateral movement of 2 1/4″ at 1250°F and 120 psig. The bellows longitudinal seam was 100% x-rayed, all welds were dye penetrant-examined and the unit hydrotested prior to shipment.

60″ Dia. Universal Expansion Joint Designed for a Chemical Company

U.S. Bellows, Inc. designed and fabricated a universal expansion joint for chemical company. The expansion joint is 60″ in diameter and 72″ in overall length. This unit is designed for 3.25″ lateral movement with a 3,620 lb./in. axial spring rate, a 131″ water column with a temperature of 220°F. An x-ray test and dye-penetrant examination were conducted on the bellows longitudinal seam weld as well as an air, soap, and bubble test prior to shipment

Universal Expansion Joint Refurbished for a Manufacturing Facility in Tennessee

This universal expansion joint was refurbished for a manufacturing facility in Tennessee. The bellows were fabricated from 304 stainless steel. The expansion joint was designed for an operating temperature of 475°F and a pressure of 127 psig. The unit is 16″ diameter by 123″ long and it is capable of 3/4″ lateral movement. A dye penetrant exam and hydro-test was conducted prior to shipment.

42″ Dia. Universal Expansion Joint Designed with Pantographic Linkage and Slotted Hinges for a Flue Gas Application

This 42″ dia., 118″ long universal expansion joint was designed with pantographic linkage and slotted hinges for flue gas application in a Columbian refinery. The redundant two-ply testable bellows are fabricated from Inconel 625 LCF and the remainder of the assembly was fabricated with refractory lined carbon steel. It is designed for an axial movement of 1.3″ at 1,000°F and 50 psig. All welds were 100% dye penetrant examined, the bellows longitudinal seam and pipe seams were 100% X-ray examined. The complete assembly was pneumatically tested to 50 psig.

81 Universal Expansion Joints Designed for California Refinery

U.S. Bellows, Inc. custom designed eighty-one universal expansion joints for an oil refinery in California. The bellows are fabricated from 304 stainless steel, and the pipe and flanges are carbon steel. The units range from 1″ to 8″ in diameter and are designed for a spring rate of 20 lb./in. The expansion joints are designed for 140°F at 25 psig and are capable of 1″ axial compression. Each unit was hydro-tested prior to shipment.

Read More36″ and 18″ Diameter Universal Expansion Joints Designed for an Oil Refinery in the Philiphines

U.S. Bellows custom designed universal expansion joints for an oil refinery in the Philippines. The bellows and liner are fabricated from 304 stainless steel and the cover, tie rods, flanges and pipe spool are carbon steel. The sizes are 18″ dia. x 60.5″ long, 28″ dia. x 80.75″ and 36″ dia. x 40″ long. The units are designed with movement indicators and for 50 psig at 655°F. They are capable of 0.675″ compression, 0.375″ lateral and 1″ angular. The bellows and pipes were 100% x-rayed, PMI examined and hydro-tested

Read More24″ Dia. Universal Expansion Joint Designed for a Refinery in Europe

U.S. Bellows designed and manufactured this universal expansion joint in accordance with ASME section VIII for an oil and gas refinery in Europe. A U2A- form was furnished as part of the units’ documentation. The expansion joint has a 24″ diameter and 103″ overall length. The bellows, liners and covers are fabricated from 316 stainless steel, and the flanges, tie-rods and pipe are carbon steel. The unit is designed for an operating temperature of 181°F at 101 psig and 1″ axial movement with a 3″ lateral offset. The bellows and pipe longitudinal weld seams were x-rayed, dye-penetrant and hydro- tested prior to shipment

Read MoreUniversal Expansion Joints Custom Designed for a Bioenergy Plant

These universal metallic expansion joints were custom designed for a pipe line in a bioengergy plant. They range from 20″ to 30″ in diameter, and are designed for 2″ lateral movement with a 1,362 lb/in. spring rate. The expansion joints are fabricated entirely from 304 stainless steel and designed for 250°F and 30 psig. Each unit was 100% dye penetrant examined and air tested prior to shipment.

Read MorePressure Balanced Tee Expansion Joint Designed for a Boiler Feed Pump Turbine Exhaust

| Type: | Single Expansion Joint |

| Size: | 96″ Dia. x 288″ OAL |

| Material: | carbon steel with 304 stainless steel |

| Design: | 2″ axial movement at 315°F and 15 psig |

| Testing: | 100% Pneumatic-tested |

This pressure balanced tee expansion joint was custom designed for a boiler feed pump turbine exhaust in a power plant. It is 96″ Dia. x 288″ OAL and fabricated from carbon steel with 304 stainless steel bellows, turning vanes and liners. It is designed for 2″ axial movement at 315°F and 15 psig. The expansion joint was dye penetrant examined, and a chemical cleaning of the interior surfaces was performed to remove any oil and grease. U.S. Bellows also performed a pneumatic test at 23 psig.

Read MoreUniversal Expansion Joint with Refractory Lining and Pantographic Linkage

U.S. Bellows, Inc. fabricated this 28″ dia., 109″ long universal expansion joint with 1″ thick AA-22 abrasion resistant refractory lining and pantographic linkage for a FCC unit in an oil refinery. The entire assembly is fabricated from 304H stainless steel with carbon steel pantographs. This expansion joint has two-ply testable bellows with wire mesh strip between the plies. It is designed for an axial movement of 5″, a lateral movement of 5-1/2″ at 1425°F and 45 psig. This unit was 100% dye penetrant tested, all pressure retaining welds were 100% radiographed and the unit was pneumatic tested prior to shipping to Oklahoma.

Read MoreCustom Designed Universal Expansion Joint for Gas Turbine Application

This custom designed universal expansion joint is to be used for a gas turbine application. Dimensions are 30” DIA x 90” OAL and materials used for fabrication were 321 ss bellows, liners, and carbon steel pipes. This expansion joint was 100% x-ray, dye-penetrant, and hydro tested. Operating conditions were 96 PSIG at 550°F for 2″ lateral and 3/8” axial compression.

Read More42″ Dia. Stainless Steel Expansion Joints for an Offshore Application

These universal metallic expansion joints were custom designed for an offshore application. They are 42″ diameter, 24″ overall length and designed for 2″ axial movement and 1-1/2″ lateral movement. The expansion joints are fabricated entirely from 316 L stainless steel and designed for 1,000°F and 1 psig. Each unit was 100% dye penetrant examined and soap and air tested prior to shipment.

12″ Dia. Universal Expansion Joints with Stainless Steel Bellows

These universal metallic expansion joints were custom designed for a chemical plant in Texas. They are fabricated entirely from stainless steel with 304 stainless steel bellows. The expansion joints are 12″ diameter, 77-1/2″ long and designed for 4-1/2″ axial movement and 2″ lateral movement. They were designed for 200°F and 100 psig. Each unit was 100% dye penetrant examined and hydrotested prior to shipment.

102″ Dia. Tied Universal and Hinged Expansion Joints

| Type: | Single Expansion Joint |

| Size: | 102″ diameter, 225″ long, 102″ diameter, 71″ long |

| Material: | carbon steel with 316 stainless |

| Design | 8.2″ lateral movement, 0.76° angular rotation, 250°F at 7.25 psig |

| Testing: | 100% X-Rayed | Dye-penetrant | Soap/Air-tested |

U.S. Bellows designed and fabricated tied universal expansion joints and single hinged expansion joints for a power plant in Canada. All the units were fabricated from carbon steel with 316 stainless steel bellows. The universal tied joints are 102″ diameter, 225″ long and are designed for 8.2″ lateral movement. The hinged joints are 102″ diameter, 71″ long and designed for 0.76° angular rotation. Each expansion joint can withstand temperatures up to 250°F at 7.25 psig. The bellows and pipe long seams were 100% x-rayed, and all the welds were 100% dye penetrant tested. A soap and air test were performed prior to shipment.

Read More