3 inch, 3.5 inch, 4 inch Nominal Diameter

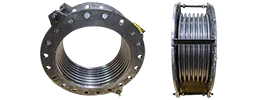

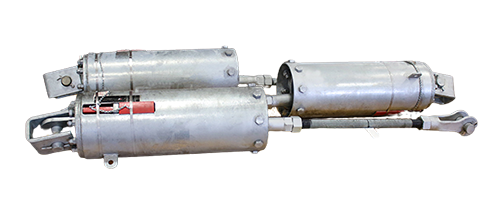

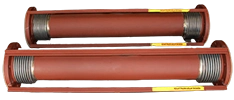

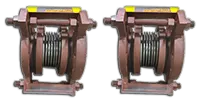

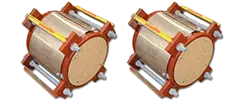

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 24 | in.

Overall Length | 36 | in.

Overall Length | 48 | in.

Overall Length | Movement | Spring Rate |

| 610 | mm

Overall Length | 914 | mm

Overall Length | 1219 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 3 | 75 | 3.17 | 16 | 8.93 | 3 | 14.93 | 1 | 2.05 | 152 |

| 5.3 | 81 | 0.3 | 227 | 0.05 | 379 | 0.02 | 52 | 3 |

| 500 | 1.33 | 91 | 3.39 | 18 | 5.49 | 7 | 0.71 | 1010 |

| 35.1 | 34 | 1.6 | 86 | 0.32 | 139 | 0.13 | 18 | 18 |

| 3.5 | 75 | 2.81 | 23 | 7.82 | 4 | 13.03 | 2 | 2 | 175 |

| 5.3 | 71 | 0.4 | 199 | 0.07 | 331 | 0.04 | 51 | 3 |

| 500 | 1.1 | 151 | 2.77 | 30 | 4.48 | 12 | 0.65 | 1355 |

| 35.1 | 28 | 2.7 | 70 | 0.54 | 114 | 0.21 | 17 | 24 |

| 4 | 50 | 3.43 | 19 | 9.41 | 3 | 15.61 | 1 | 2.71 | 111 |

| 3.5 | 87 | 0.3 | 239 | 0.05 | 396 | 0.02 | 69 | 2 |

| 275 | 1.44 | 106 | 3.53 | 22 | 5.66 | 9 | 0.92 | 775 |

| 19.3 | 37 | 1.9 | 90 | 0.39 | 144 | 0.16 | 23 | 14 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50-75 PSIG Series: 150 lb. ANSI B16.5 RPSO.

275-500 PSIG Series: 300 lb. ANSI B16.5 RPSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106.

50-75 PSIG Series: Std. Wt. Pipe.

275-500 PSIG Series: Std. Wt. Pipe

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

5 inch, 6 inch, 8 inch Nominal Diameter

Flanged Universal Exapnsion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/ Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 30 | in.

OverallLength | 42 | in.

OverallLength | 54 | in.

OverallLength | Movement | Spring Rate |

| 762 | mm

OverallLength | 1067 | mm | 1372 | mm

OverallLength |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 5 | 75 | 4.96 | 12 | 9.61 | 4 | 14.33 | 2 | 2.47 | 139 |

| 5.3 | 126 | 0.2 | 244 | 0.07 | 364 | 0.04 | 63 | 2 |

| 275 | 1.78 | 87 | 3.26 | 29 | 4.75 | 14 | 0.77 | 1160 |

| 19.3 | 45 | 1.6 | 83 | 0.52 | 121 | 0.25 | 20 | 21 |

| 6 | 70 | 3.59 | 22 | 7.44 | 6 | 11.34 | 3 | 2.43 | 143 |

| 4.9 | 91 | 0.4 | 189 | 0.11 | 288 | 0.05 | 62 | 3 |

| 200 | 2.01 | 104 | 4.17 | 29 | 6.36 | 13 | 1.36 | 665 |

| 14.1 | 51 | 1.9 | 106 | 0.52 | 162 | 0.23 | 35 | 12 |

| 500 | 0.65 | 1017 | 1.38 | 259 | 2.12 | 115 | 0.46 | 5473 |

| 35.1 | 17 | 18.2 | 35 | 4.63 | 54 | 2.06 | 12 | 98 |

| 8 | 45 | 3.62 | 40 | 8.31 | 10 | 13.19 | 4 | 3.91 | 126 |

| 3.2 | 92 | 0.7 | 211 | 0.18 | 335 | 0.07 | 99 | 2 |

| 200 | 1.89 | 186 | 4.34 | 46 | 6.89 | 20 | 2.05 | 583 |

| 14.1 | 48 | 3.3 | 110 | 0.82 | 175 | 0.36 | 52 | 10 |

| 400 | 0.71 | 1576 | 1.66 | 364 | 2.64 | 157 | 0.77 | 4314 |

| 28.1 | 18 | 28.2 | 42 | 6.51 | 67 | 2.81 | 20 | 77 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

40-75 PSIG Series: 150 lb. ANSI B16.5 RFSO.

200-275 PSIG Series: 150 lb. ANSI B16.5 RFSO

400-500 PSIG Series: 300 lb. ANSI B16.5 RFSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106.

40-75 PSIG Series: Std. Wt. Pipe.

200-275 PSIG Series: Std. Wt. Pipe.

400-500 PSIG Series: Std. Wt. Pipe.

Liners: A240-T304.

Covers: Carbon steel.

10 inch, 12 inch, 14 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/ Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 24 | in.

Overall Length | 36 | in.

Overall Length | 48 | in.

Overall Length | Movement | Spring Rate |

| 610 | mm

Overall Length | 914 | mm

Overall Length | 1219 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 10 | 45 | 6.26 | 49 | 11.8 | 18 | 17.63 | 9 | 6.08 | 213 |

| 3.2 | 159 | 0.9 | 300 | 0.32 | 448 | 0.16 | 154 | 4 |

| 260 | 2.72 | 256 | 5.04 | 92 | 7.45 | 47 | 2.48 | 1127 |

| 18.3 | 69 | 4.6 | 128 | 1.65 | 189 | 0.84 | 63 | 20 |

| 12 | 45 | 5.07 | 80 | 10.01 | 27 | 15.23 | 13 | 6.4 | 208 |

| 3.2 | 129 | 1.4 | 254 | 0.48 | 387 | 0.23 | 163 | 4 |

| 200 | 2.41 | 369 | 4.67 | 123 | 7.02 | 60 | 2.85 | 976 |

| 14.1 | 61 | 6.6 | 119 | 2.2 | 178 | 1.07 | 72 | 17 |

| 14 | 50 | 4.8 | 95 | 9.24 | 33 | 13.9 | 16 | 6.23 | 229 |

| 3.5 | 122 | 1.7 | 235 | 0.59 | 353 | 0.29 | 158 | 4 |

| 200 | 2.04 | 548 | 3.92 | 184 | 5.87 | 91 | 2.56 | 1255 |

| 14.1 | 52 | 9.8 | 100 | 3.29 | 149 | 1.63 | 65 | 22 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

45-50 PSIG Series: 150 lb. ANSI B16.5 RPSO.

200-260 PSIG Series: 300 lb. ANSI B16.5 RPSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106.

45-50 PSIG Series: Std. Wt. Pipe.

200-260 PSIG Series: Std. Wt. Pipe

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon Steel

16 inch, 18 inch, 20 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/ Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 48 | in.

Overall Length | 60 | in.

Overall Length | 72 | in.

Overall Length | Movement | Spring Rate |

| 1219 | mm

Overall Length | 1524 | mm

Overall Length | 1829 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 16 | 35 | 6.73 | 70 | 11.6 | 29 | 16.7 | 16 | 7.75 | 211 |

| 2.5 | 171 | 1.3 | 295 | 0.52 | 424 | 0.29 | 197 | 4 |

| 200 | 3.11 | 339 | 5.06 | 149 | 7.05 | 83 | 2.96 | 1235 |

| 14.1 | 79 | 6.1 | 129 | 2.67 | 179 | 1.49 | 75 | 22 |

| 400 | 2.45 | 843 | 3.98 | 363 | 5.54 | 200 | 2.3 | 2894 |

| 28.1 | 62 | 15.1 | 101 | 6.5 | 141 | 3.58 | 58 | 52 |

| 18 | 40 | 5.91 | 98 | 10.18 | 41 | 14.66 | 22 | 7.59 | 238 |

| 2.8 | 150 | 1.8 | 259 | 0.73 | 372 | 0.39 | 193 | 4 |

| 200 | 2.48 | 550 | 4.16 | 230 | 5.88 | 125 | 2.85 | 1394 |

| 14.1 | 63 | 9.8 | 106 | 4.12 | 149 | 2.24 | 72 | 25 |

| 400 | 1.97 | 1365 | 3.16 | 595 | 4.37 | 331 | 1.98 | 3919 |

| 28.1 | 50 | 24.4 | 80 | 10.65 | 111 | 5.92 | 50 | 70 |

| 20 | 45 | 5.24 | 133 | 9.03 | 55 | 12.99 | 30 | 7.43 | 265 |

| 3.2 | 133 | 2.4 | 229 | 0.98 | 330 | 0.54 | 189 | 5 |

| 200 | 2.26 | 725 | 3.75 | 306 | 5.27 | 167 | 2.77 | 1533 |

| 14.1 | 57 | 13 | 95 | 5.48 | 134 | 2.99 | 70 | 28 |

| 400 | 1.59 | 2120 | 2.62 | 881 | 3.66 | 479 | 1.88 | 4365 |

| 28.1 | 40 | 37.9 | 67 | 15.77 | 93 | 8.57 | 48 | 78 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

35-45 PSIG Series: 125 lb. Lt/Wt FFSO.

200 PSIG Series: 150 lb. ANSI B16.5 RFSO

400 PSIG Series: 300 lb. ANSI B16.5 RFSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106.

35-45 PSIG Series: Std. Wt. Pipe.

200 PSIG Series: Std. Wt. Pipe.

400 PSIG Series: Std. Wt. Pipe.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

22 inch, 24 inch, 26 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

|

Size

|

Pressure

|

Non-concurrant Movements/Spring Rates

|

|

Lateral Movement/Spring Rates

|

Axial

|

|

48

|

in.

Overall Length

|

60

|

in.

Overall Length

|

72

|

in.

Overall Length

|

Movement

|

Spring Rate

|

|

1219

|

mm

Overall Length

|

1524

|

mm

Overall Length

|

1829

|

mm

Overall Length

|

|

Movement

|

Spring Rate

|

Movement

|

Spring Rate

|

Movement

|

Spring Rate

|

|

PSIG

|

in.

|

lb./in.

|

in.

|

lb./in.

|

in.

|

lb./in.

|

in.

|

lb./in.

|

|

kg/cm2

|

mm

|

kg/mm

|

mm

|

kg/mm

|

mm

|

kg/mm

|

mm

|

kg/mm

|

|

22

|

45

|

5.28

|

137

|

8.88

|

58

|

12.62

|

32

|

7.62

|

243

|

|

3.2

|

134

|

2.5

|

226

|

1.04

|

321

|

0.57

|

194

|

4

|

|

165

|

2.24

|

811

|

3.66

|

347

|

5.12

|

191

|

2.9

|

1497

|

|

11.6

|

57

|

14.5

|

93

|

6.21

|

130

|

3.42

|

74

|

27

|

|

350

|

1.48

|

2536

|

2.40

|

1069

|

3.33

|

585

|

1.84

|

4506

|

|

24.6

|

38

|

45.4

|

61

|

19.13

|

85

|

10.47

|

47

|

81

|

|

24

|

50

|

4.74

|

177

|

7.98

|

75

|

11.34

|

41

|

7.43

|

266

|

|

3.5

|

120

|

3.2

|

203

|

1.34

|

288

|

0.73

|

189

|

5

|

|

160

|

2.06

|

1024

|

3.36

|

441

|

4.68

|

243

|

2.85

|

1636

|

|

11.2

|

52

|

18.3

|

85

|

7.89

|

119

|

4.35

|

72

|

29

|

|

350

|

1.34

|

3163

|

2.15

|

1347

|

2.97

|

741

|

1.75

|

4925

|

|

24.6

|

34

|

56.6

|

55

|

24.11

|

75

|

13.26

|

44

|

88

|

|

26

|

50

|

3.88

|

268

|

6.83

|

107

|

9.91

|

57

|

7.37

|

289

|

|

3.5

|

99

|

4.8

|

173

|

1.91

|

252

|

1.02

|

187

|

5

|

|

165

|

1.87

|

1450

|

3.41

|

544

|

5.02

|

281

|

3.85

|

1332

|

|

11.6

|

47

|

25.9

|

87

|

9.74

|

128

|

5.03

|

98

|

24

|

|

335

|

1.55

|

3635

|

2.99

|

1252

|

4.52

|

622

|

3.67

|

2672

|

|

23.5

|

39

|

65.1

|

76

|

22.41

|

115

|

11.13

|

93

|

48

|

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

45-50 PSIG Series: 125 lb. Lt/Wt FFSO

160-165 PSIG Series: 150 lb. ANSI B16.5 RFSO

335-350 PSIG Series: 300 lb. ANSI B16.5 RFSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106/A-285-C

45-50 PSIG Series: Std. Wt. Pipe/0.375-inch wall.

160-165 PSIG Series: Std. Wt. Pipe/0.375-inch wall.

335-350 PSIG Series: 0.500-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

28 inch, 30 inch, 32 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 48 | in.

Overall Length | 60 | in.

Overall Length | 72 | in.

Overall Length | Movement | Spring

Rate |

| 1219 | mm

Overall Length | 1524 | mm

Overall Length | 1829 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 28 | 50 | 3.61 | 333 | 6.36 | 132 | 9.22 | 70 | 7.36 | 311 |

| 3.5 | 92 | 6 | 162 | 2.36 | 234 | 1.25 | 187 | 6 |

| 160 | 1.74 | 1801 | 3.17 | 675 | 4.67 | 348 | 3.85 | 1437 |

| 11.2 | 44 | 32.2 | 81 | 12.08 | 119 | 6.23 | 98 | 26 |

| 315 | 1.45 | 4512 | 2.82 | 1554 | 4.25 | 772 | 3.71 | 2881 |

| 22.1 | 37 | 80.7 | 72 | 27.81 | 108 | 13.82 | 94 | 52 |

| 30 | 50 | 3.65 | 316 | 6.41 | 126 | 9.3 | 67 | 7.96 | 257 |

| 3.5 | 93 | 5.7 | 163 | 2.25 | 236 | 1.2 | 202 | 5 |

| 135 | 1.91 | 1708 | 3.48 | 640 | 5.13 | 330 | 4.53 | 1185 |

| 9.5 | 49 | 30.6 | 88 | 11.45 | 130 | 5.91 | 115 | 21 |

| 290 | 1.55 | 4276 | 3 | 1473 | 4.52 | 731 | 4.23 | 2376 |

| 20.4 | 39 | 76.5 | 76 | 26.36 | 115 | 13.08 | 107 | 43 |

| 32 | 50 | 3.43 | 382 | 6.03 | 152 | 8.75 | 80 | 7.96 | 274 |

| 3.5 | 87 | 6.8 | 153 | 2.72 | 222 | 1.43 | 202 | 5 |

| 135 | 1.79 | 2062 | 3.27 | 773 | 4.82 | 399 | 4.53 | 1266 |

| 9.5 | 45 | 36.5 | 83 | 13.83 | 122 | 7.14 | 115 | 23 |

| 290 | 1.45 | 5163 | 2.81 | 1778 | 4.25 | 883 | 4.23 | 2537 |

| 20.4 | 37 | 92.4 | 71 | 31.82 | 108 | 15.8 | 107 | 45 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50 PSIG Series: 125 lb Lt/Wt FFSO.

For 135-160 PSIG Series and 290-315 PSIG Series: Customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/APJ-5L/A-285-C.

50 PSIG Series: 0.375-inch wall.

135-160 PSIG Series: 0.375-inch wall.

290-315 PSIG Series: 0.500-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

34 inch, 36 inch, 38 inch Nominal Diameter

Flanged Universal Expasnion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Llateral Movement/Spring Rates | Axial |

| 54 | in.

Overall Length | 66 | in.

Overall Length | 78 | in.

Overall Length | Movement | Spring Rate |

| 1372 | mm

Overall Length | 1676 | mm

Overall Length | 1981 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 34 | 50 | 4.44 | 273 | 6.97 | 129 | 9.56 | 74 | 7.96 | 292 |

| 3.5 | 113 | 4.9 | 177 | 2.31 | 243 | 1.32 | 202 | 5 |

| 135 | 2.13 | 1683 | 3.54 | 723 | 5.01 | 398 | 4.5 | 1346 |

| 9.5 | 54 | 30.1 | 90 | 12.94 | 127 | 7.12 | 114 | 24 |

| 275 | 1.58 | 4951 | 2.89 | 1856 | 4.25 | 958 | 4.24 | 2699 |

| 19.3 | 40 | 88.6 | 73 | 33.21 | 108 | 17.14 | 108 | 48 |

| 36 | 50 | 4.21 | 323 | 6.59 | 152 | 9.05 | 88 | 7.96 | 309 |

| 3.5 | 107 | 5.8 | 167 | 2.72 | 230 | 1.57 | 202 | 6 |

| 135 | 2.02 | 1991 | 3.35 | 854 | 4.74 | 471 | 4.49 | 1427 |

| 9.5 | 51 | 35.6 | 85 | 15.28 | 120 | 8.43 | 114 | 26 |

| 250 | 1.52 | 5853 | 2.78 | 2194 | 4.09 | 1132 | 4.31 | 2860 |

| 17.6 | 39 | 104.7 | 71 | 39.26 | 104 | 20.26 | 109 | 51 |

| 38 | 50 | 3.99 | 379 | 6.26 | 179 | 8.59 | 103 | 7.96 | 327 |

| 3.5 | 101 | 6.8 | 159 | 3.2 | 218 | 1.84 | 202 | 6 |

| 130 | 1.93 | 2333 | 3.21 | 1001 | 4.53 | 552 | 4.52 | 1508 |

| 9.1 | 49 | 41.8 | 82 | 17.91 | 115 | 9.88 | 115 | 27 |

| 250 | 1.44 | 6859 | 2.64 | 2571 | 3.88 | 1327 | 4.3 | 3021 |

| 17.6 | 37 | 122.7 | 67 | 46.01 | 99 | 23.75 | 109 | 54 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50 PSIG Series: 125 lb. Lt/Wt FFSO.

For 130-135 PSIG Series and 250-275 PSIG Series: Customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-285-C.

50 PSIG Series: 0.375-inch wall

130-135 PSIG Series: 0.375-inch wall.

250-275 PSIG Series: 0.500-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

40 Inch, 42 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 54 | in.

Overall Length | 66 | in.

Overall Length | 78 | in.

Overall Length | Movement | Spring

Rate |

| 1372 | mm

Overall Length | 1676 | mm

Overall Length | 1981 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 40 | 50 | 3.45 | 515 | 5.59 | 231 | 7.8 | 130 | 7.96 | 344 |

| 3.5 | 88 | 9.2 | 142 | 4.13 | 198 | 2.33 | 202 | 6 |

| 120 | 1.66 | 3254 | 2.88 | 1312 | 4.15 | 700 | 4.58 | 1588 |

| 8.4 | 42 | 58.2 | 73 | 23.48 | 105 | 12.53 | 116 | 28 |

| 225 | 1.21 | 9928 | 2.35 | 3419 | 3.55 | 1698 | 4.37 | 3183 |

| 15.8 | 31 | 177.7 | 60 | 61.18 | 90 | 30.39 | 111 | 57 |

| 42 | 50 | 3.29 | 595 | 5.34 | 267 | 7.45 | 150 | 7.96 | 362 |

| 3.5 | 84 | 10.6 | 136 | 4.78 | 189 | 2.68 | 202 | 6 |

| 115 | 1.59 | 3756 | 2.77 | 1514 | 3.99 | 809 | 4.61 | 1669 |

| 8.1 | 40 | 67.2 | 70 | 27.09 | 101 | 14.48 | 117 | 30 |

| 225 | 1.16 | 11459 | 2.24 | 3946 | 3.39 | 1960 | 4.37 | 3344 |

| 15.8 | 29 | 205.1 | 57 | 70.62 | 86 | 35.08 | 111 | 60 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50 PSIG Series: 125 lb. Lt/Wt FFSO.

For 115-120 PSIG Series and 225 PSIG Series: Customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-53/A-106.

50-75 PSIG Series: Std. Wt. Pipe.

275-500 PSIG Series: Std. Wt. Pipe

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

44 inch, 46 inch, 48 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 48 | in.

Overall Length | 60 | in.

Overall Length | 72 | in.

Overall Length | Movement | Spring

Rate |

| 1219 | mm

Overall Length | 1524 | mm

Overall Length | 1829 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 44 | 50 | 2.42 | 1008 | 4.14 | 412 | 5.93 | 221 | 7.02 | 427 |

| 3.5 | 61 | 18 | 105 | 7.37 | 151 | 3.95 | 178 | 8 |

| 115 | 1.2 | 6238 | 2.28 | 2184 | 3.41 | 1094 | 4.5 | 1750 |

| 8.1 | 30 | 111.6 | 58 | 39.08 | 87 | 19.58 | 114 | 31 |

| 46 | 35 | 2.3 | 729 | 3.95 | 298 | 5.65 | 160 | 7.02 | 281 |

| 2.5 | 58 | 13 | 100 | 5.33 | 144 | 2.86 | 178 | 5 |

| 95 | 1.44 | 4513 | 2.75 | 1581 | 4.11 | 792 | 5.69 | 1150 |

| 6.7 | 37 | 80.8 | 70 | 28.29 | 104 | 14.17 | 145 | 21 |

| 48 | 35 | 2.16 | 907 | 3.65 | 375 | 5.19 | 203 | 6.58 | 335 |

| 2.5 | 55 | 16.2 | 93 | 6.71 | 132 | 3.63 | 167 | 6 |

| 95 | 1.3 | 5572 | 2.44 | 1984 | 3.62 | 1002 | 5.09 | 1372 |

| 6.7 | 33 | 99.7 | 62 | 35.5 | 92 | 17.93 | 129 | 25 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

35-50 PSIG Series: 125 lb. Lt/Wt FFSO.

95-115 PSIG Series: Customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-285-C

35-50 PSIG Series: 0.375-inch wall

95-115 PSIG Series: 0.375-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

50 inch Through 72 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Size | Pressure | Non-concurrant Movements/Spring Rates |

| Lateral Movement/Spring Rates | Axial |

| 50 | in.

Overall Length | 66 | in.

Overall Length | 78 | in.

Overall Length | Movement | Spring Rate |

| 1270 | mm

Overall Length | 1676 | mm

Overall Length | 1981 | mm

Overall Length |

| Movement | Spring

Rate | Movement | Spring

Rate | Movement | Spring

Rate |

| PSIG | in. | lb./in. | in. | lb./in. | in. | lb./in. | in. | lb./in. |

| kg/cm 2 | mm | kg/mm | mm | kg/mm | mm | kg/mm | mm | kg/mm |

| 50 | 75 | 1.74 | 3751 | 2.9 | 1610 | 4.1 | 887 | 5.4 | 1393 |

| 5.3 | 44 | 67.1 | 74 | 28.81 | 104 | 15.87 | 137 | 25 |

| 52 | 70 | 1.69 | 4209 | 2.81 | 1807 | 3.97 | 995 | 5.44 | 1450 |

| 4.9 | 43 | 75.3 | 71 | 32.34 | 101 | 17.81 | 138 | 26 |

| 54 | 70 | 1.46 | 5641 | 2.53 | 2274 | 3.64 | 1214 | 5.44 | 1506 |

| 4.9 | 37 | 100.9 | 64 | 40.69 | 92 | 21.73 | 138 | 27 |

| 60 | 60 | 1.26 | 8122 | 2.21 | 3205 | 3.2 | 1696 | 5.31 | 1677 |

| 4.2 | 32 | 145.3 | 56 | 57.36 | 81 | 30.35 | 135 | 30 |

| 66 | 55 | 1.16 | 10757 | 2.03 | 4245 | 2.93 | 2246 | 5.34 | 1847 |

| 3.9 | 29 | 192.5 | 52 | 75.97 | 74 | 40.19 | 136 | 33 |

| 72 | 50 | 1.01 | 15372 | 1.82 | 5845 | 2.66 | 3041 | 5.4 | 2017 |

| 3.5 | 26 | 275.1 | 46 | 104.65 | 68 | 54.42 | 137 | 36 |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

50-75 PSIG Series: 125 lb. Lt/Wt FFSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-285-C.

50-75 PSIG Series: 0.375-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel

84 inch Through 144 inch Nominal Diameter

Flanged Universal Expansion Joint

View PDF

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section.

- To increase cycle life or movements, please refer to graph on cycle life.

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Tabulated values are for tied joints, with butt weld ends. Performance of joints with flanged ends, and unrestrained joints, will exceed tabulated values.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: See catalog flange data for appropriate flange temperature/pressure ratings.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

|

Size

|

Pressure

|

Non-concurrant Movements/Spring Rates

|

|

Llateral Movement/Spring Rates

|

Axial

|

|

60

|

in.

Overall Length

|

72

|

in.

Overall Length

|

84

|

in.

Overall Length

|

Movement

|

Spring Rate

|

|

1524

|

mm

Overall Length

|

1829

|

mm

Overall Length

|

2134

|

mm

Overall Length

|

|

Movement

|

Spring

Rate

|

Movement

|

Spring

Rate

|

Movement

|

Spring

Rate

|

|

PSIG

|

in.

|

lb./in.

|

in.

|

lb./in.

|

in.

|

lb./in.

|

in.

|

lb./in.

|

|

kg/cm2

|

mm

|

kg/mm

|

mm

|

kg/mm

|

mm

|

kg/mm

|

mm

|

kg/mm

|

|

84

|

45

|

1.10

|

17326

|

1.84

|

7437

|

2.59

|

4096

|

5.65

|

2358

|

|

3.2

|

28

|

310.1

|

47

|

133.09

|

66

|

73.30

|

144

|

42

|

|

96

|

40

|

0.97

|

24772

|

1.60

|

10757

|

2.24

|

5963

|

5.45

|

2699

|

|

2.8

|

25

|

443.3

|

41

|

192.50

|

57

|

106.71

|

138

|

48

|

|

108

|

35

|

0.88

|

36505

|

1.46

|

15669

|

2.06

|

8631

|

5.74

|

3040

|

|

2.5

|

22

|

653.3

|

37

|

280.40

|

52

|

154.46

|

146

|

54

|

|

120

|

30

|

0.67

|

65983

|

1.19

|

25681

|

1.74

|

13488

|

5.79

|

3380

|

|

2.1

|

17

|

1180.8

|

30

|

459.57

|

44

|

241.37

|

147

|

60

|

|

132

|

25

|

0.61

|

87604

|

1.09

|

34096

|

1.59

|

17908

|

5.82

|

3721

|

|

1.8

|

15

|

1567.7

|

28

|

610.16

|

40

|

320.47

|

148

|

67

|

|

144

|

25

|

0.46

|

156468

|

0.89

|

53883

|

1.34

|

26764

|

5.82

|

4062

|

|

1.8

|

12

|

2800.1

|

23

|

964.26

|

34

|

478.95

|

148

|

73

|

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section.

Flanges: ASTM A105.

40-45 PSIG Series: (96″ and 84″ dia) 125 lb Lt/Wt/FFSO

25-30 PSIG Series: (108″ and 144″ dia) customer to specify actual flanges required.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A-285-C

25-45 PSIG Series: 0.375-inch wall

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel